FC/B® Connector - FC Connector at Brewster Angle

Chalcogenide As2S3 and As2Se3 glass fibers offer broad transmission range with low propagation loss from 1.5µm to 6.5µm and from 1.5µm to 10µm relatively, with high non-linear coefficient, small and negative index change with temperature (dn/dT), excellent power handling capability, and are chemically stable.

Transmission cables using these fibers can be fabricated with the known terminations such as: SMA, FC/PC and FC/APC. However, when light travels between media (for instance, glass and air), a portion of the light is reflected - a phenomenon know as Fresnel Reflection. Typical uncoated glass optical components will suffer approximately 8 -10% loss from Fresnel Reflections depending on the wavelength of light and the index of refraction of the material. Due to the high refractive index of chalcogenide glasses (~2.4 for As2S3, and ~2.7 for As2Se3), the fibers experience a large Fresnel reflection (17% for As2S3, and 21% for As2Se3) at the input and output faces.

For cables with SMA or FC/PC termination, this reflection at the input could cause undesirable effects on lasers or other optical components. For applications where this reflection needs to be eliminated, isolators must be used. FC/APC termination with 8° angle at the input face does not alleviate the back reflection problems. However, the above termination will still experience lower power being transmitted because of the power loss due to these reflections.

IRflex’s FC/B® termination allows the input beam to be nearly fully transmitted at the input face. Therefore, in addition to eliminating undesirable back reflections, more power is being coupled into the fiber.

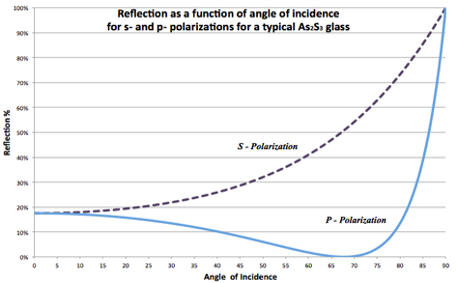

IRflex’s FC/B® connector achieves nearly full transmission and no reflection at the input face by using the Brewster angle feature of transmissive materials. Light incident on a material at its Brewster angle will experience no reflection for light with its electric field parallel to the plane of incidence; this is called TM or P-polarization. Light with TE or S-polarization will still experience reflection; as such this angle is also called the polarizing angle. As seen in Figure1.

Figure 1: Reflection as a function of incident angle for S- and P-polarizations for an air-to-As2S3 interface. It can be seen that for a certain angle the P-polarization experiences 0% reflection.

Figure 1: Reflection as a function of incident angle for S- and P-polarizations for an air-to-As2S3 interface. It can be seen that for a certain angle the P-polarization experiences 0% reflection.

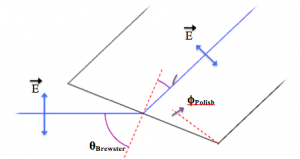

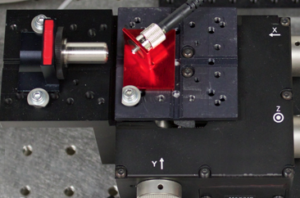

IRflex’s FC/B® connector is polished at a predetermined angle that permits the incident light to arrive at the Brewster angle when used in conjunction with the custom-made FC/B® holder. Normally, light incident at the Brewster angle will be transmitted at an angle with respect to the surface normal, and this angle is not along the fiber’s axis that allows the incident beam to escape to the cladding and not be guided. FC/B®’s polish angle, together with the holder, allows the input beam to be incident at the Brewster angle and be transmitted along the axis of the fiber to achieve a successful coupling. The FC/B® connector can only work well at the input side. FC/B ®at the output side is not guaranteed to work, as the fiber does not preserve polarization state. For nearly full transmission at the input, the beam needs to be in the TM or P-polarization state, as seen in Figure 2.

Figure 2: Diagram showing the input beam polarization for maximum transmission. Additionally, the relevant angles are shown.

Figure 2: Diagram showing the input beam polarization for maximum transmission. Additionally, the relevant angles are shown.

The FC/B® connector’s polish angle was determined that all input light within a cone with NA of 0.21 experiences 5% or less reflection. Additionally, this also gives good tolerances on the alignment of the incoming beam. See Figure 3 for the coupling setup.

Figure 3: Setup for coupling into the FC/B® connector end using the FC/B® holder