Research

Research Projects

IRflex’s scientific and engineering team has vast experience in the development and manufacturing of innovative fiber-optic devices for the mid-infrared. Our outstanding knowledge and expertise in specialty optical fiber technology support the development and production of custom active and passive devices for the military, biomedical, and chemical sensing applications.

Besides working on our-own R&D projects, we also perform Small Business Innovation Research (SBIR) and the Small Business Technology Transfer (STTR) programs exploring new concepts. We conduct funded research and development programs to push the edges of mid-IR devices using our chalcogenide glass/fibers.

The Small Business Innovation Research (SBIR) program is a highly competitive program that encourages domestic small businesses to engage in Federal Research/Research and Development (R/R&D) that has the potential for commercialization. The Small Business Technology Transfer (STTR) is another program that expands funding opportunities in the federal innovation research and development (R&D) arena. Central to the program is expansion of the public/private sector partnership to include the joint venture opportunities for small businesses and nonprofit research institutions. The unique feature of the STTR program is the requirement for the small business to formally collaborate with a research institution in Phase I and Phase II.

Past and current SBIR/STTR

IRflex has won more than 20 of SBIR (Small Business Innovation Research) and STTR (Small Business Technology Transfer) Phase I & Phase II Project awards with total value of 8 million US$ from US Government Agencies (Navy, Air Force, Army), to name some of the projects:

- High Performance Optical Fibers for 100-Watts infrared Lasers

- Additive Nanostructures for Broadband Antireflectivity

- Mid-Wave Infrared Fiber Amplifier

- Mid-Wave Infrared Polarization-Maintaining Single Mode Fiber

- Lasers Based on Gas or Liquid Filled Hollow-Core Photonic Crystal Fibers

- Chalcogenide Glass Mid-IR Acrylindrical Lens Development

- New Mid-IR Laser Power Scaling Technology via Chalcogenide Fiber Combiner

- Chalcogenide Infrared Fiber Manufacturing Technology

- Fiber Delivery Systems for Ultrashort Pulse Lasers

- Mid-Infrared Fiber Coupler for Multiband Infrared Countermeasure (IRCM) Lasers

- Mid-Infrared Fiber Bundle Imager

- Laser Beam Delivery Sub-System for Multi-Band Mid-Infrared Laser

- High Average Power Super continuum in the mid-infrared

- Mid-infrared Fiber-Optic Switch for IRCM Laser Application

Current and past research projects Include:

Novel patented Hollow-Core Chalcogenide Fiber with Anti-Resonant Arches for High-Power Infrared Laser – Patent No. US 10,816,721 B1

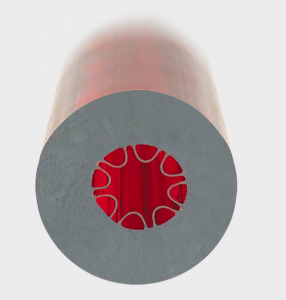

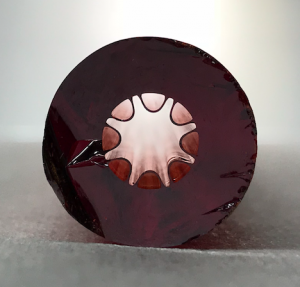

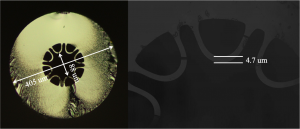

Hollow-core anti-resonant (HC-AR) fiber is an alternative approach to hollow-core photonic band gap fiber to minimize the light overlap in the glass struts and to transmit very high power/energy laser. The anti-resonance in the thin glass struts at the interface of the hollow core and the cladding efficiently reflects and confines the light in the hollow core. Silica HC-AR fiber cannot transmit wavelengths >4.5 micron because the small portion of the guided light that interacts with the silica glass struts is highly absorbed and light does not propagate far. The use of infrared chalcogenide glass for the fabrication of HC-AR fiber is attractive for extending laser transmission to longer wavelengths in the infrared (1-15 micron). IRflex innovative hollow-core fiber with anti-resonant arches (HC-ARA) is designed and made of chalcogenide glass. The HC-ARA fiber has a single layer of non-touching curved aches, each one being solidly attached at two locations on the outer solid region to prevent any lateral displacement and to preserve the arches’ shape and uniformity during the fabrication process. The thickness and spacing between the arches are selected to minimize the fiber transmission loss <0.1 dB/m at specific wavelength bands. Also the higher order modes of the HC-ARA fiber are more attenuated than the fundamental mode, so the fiber is effectively single mode after only a few meters.

The chalcogenide HC-ARA fiber can be designed to transmit high-power lasers in the infrared such as CO2 laser at 10.6 micron (or other wavelengths in the region of 9 -11 micron), and CO laser at 5.5 micron. Following pictures show the hollow-core preform and the HC-ARA fiber drawn from recent design.

IRflex Corporation has filled the patent of this novel design and technology in April 2019 and has been granted the patent by the United States Patent and Trademark Office on October 27, 2020. The patent no. is US 10,816,721 B1. The HC-ARA fiber will come to commercial CO and CO2 market soon.

Mid-Wave Infrared Polarization-Maintaining Single Mode Fiber

Applications requiring linearly polarized light and the flexibility of fiber delivery in the MWIR region will require a fiber solution that preserve the polarization state of the launched light. Most infrared lasers are polarized. PM-fiber offers the capability of preserving the launched light polarization state as it propagates through the fiber. In conventional fibers the polarization state is not preserved due to mechanical stress, temperature induced changes, fiber fabrication imperfections, and fiber bends. Commercially available silica PM-fibers cover the visible and near-infrared spectrum; these work by creating a strong birefringence across the core of the fiber, which is responsible for preserving the polarization state of launched light as long as the polarization is aligned with one of the birefringent axes. Currently there is no commercially available PM-fiber solution for the MWIR region.

IRflex team started from April 2019 to design a prototype specialty fiber capable of high-power laser transmission and preserving the polarization state of the input light with high polarization extinction ratio, high birefringence and with low propagation losses covering the MWIR wavelength spectrum from 2 to 6 um.

Lasers Based on Gas or Liquid Filled Hollow-Core Photonic Crystal (HCPCF)

Mid-IR generation in hollow-core photonic crystal fiber offers a potential means to mitigate the drawbacks of current pulse and continuous wave mid-IR laser sources, which rely on near IR lasers to pump a bulk nonlinear optical material that requires angle or temperature tuning to generate the desired wavelength. Current systems are mechanically complex, require free space optical alignment, and are fairly huge in size. In addition, material selection for efficient nonlinear generation of Mid-IR wavelengths and the ability to create higher peak powers are limited.

HCPCF offers a unique hybridization of fiber optic technology and gas/liquid laser technology, which can enable efficient sources of mid-IR laser emission with great flexibility in emission wavelength in a compact, mechanically-robust design. This allows the new laser system to minimize the number of free space optics, without gas containment cells, and have the potential to operate over a wider range of temperatures with greater power emission.

Since later 2016, considerable work has already been accomplished here in IRflex to develop the hollow-core fiber using our chalcogenide glass to target CO2 laser market. This 2018 reward STTR Phase I project with University of New Mexico will fuel our on-going hollow-core fiber project using chalcogenide glass to target commercial CO2 laser market as well as for applications such as LADAR seekers, target illuminators, designators, target trackers, infrared counter measures, and standoff chem-bio detection.

Chalcogenide Glass Mid-IR Acylindrical lens Development

Cylindrical micro-lens with an aspheric contour provides high NA and small focal length, but such lenses are not known to exist presently for mid-infrared. Chalcogenide glasses are a suitable material for the production of micro lenses; these are transparent from 1um to beyond 10um and offer high refractive index, low and negative dn/dT and high damage threshold. Additionally, it is suitable for high-precision molding. The proposed work will demonstrate the feasibility to develop chalcogenide glass acylindrical micro-lenses with low absorbance and high damage thresholds. Prototypes will be made with short focal length (f~1mm) and high NA (~0.8) for 4.6um wavelength. BENEFIT: Development of new chalcogenide glass lenses will benefit military applications that utilize mid-wave infrared (MWIR) laser sources capable of deliver high output powers. High-energy pulsed laser made from Fe:ZnSe delivers beam at 4.5um and is pumped at 3um. This laser would need optics with high damage thresholds and transparent in the MWIR. Also, quantum cascade lasers (QCLs) offer wavelengths from 4.5um to beyond 10um and require high numerical aperture cylindrical micro-lenses to collimate the fast axis of the laser. Both of these laser systems would greatly benefit from chalcogenide glass lenses. Chalcogenide glass offers low-loss transmission in the MWIR and beyond, it possesses a high damage threshold and can be molded with high precision. The proposed development of chalcogenide micro-lenses will focus on covering the need of the fast axis collimation of single QCL sources. However the chalcogenide cylindrical microlens can also be extended to collimate QCL arrays. Additionally, industrial and medical applications with laser sources working in the MWIR will find benefit in the development of new chalcogenide microlenses.

IRF-Se Series As2Se3 based Chalcogenide Glass Longwave Fiber (LWF)

IRF-Se series longwave fiber offers broadest transmission range from 1.5 up to 10 µm with nonlinearities approaching values of 1000 times greater than that of silica glass fiber. Multimode fibers are developed for use with medical and dental surgical instrument that utilize CO2 lasers. Singlemode fibers will be fabricated for the transmission of semiconductor lasers such as QCL, and the generation of ultra-broad supercontinuum generation, which could potentially cover the 2-10 µm range.

Mid-Infrared Fiber Bundle Imager

Fiber bundles enable images to be obtained from places inaccessible to cameras due to size and/or harsh environments. Coherent fiber bundle imagers have been used to develop medical and industrial endoscopes, and for spectral analysis. Most fiber bundle imagers cover the visible to near infrared (0.4 -1µm) spectral range. Applications such as analysis of combustion processes require coherent fiber bundles that cover the near to mid-infrared region (1-12 µm). Unfortunately, there exist no coherent fiber bundle imagers for that spectral region. IRflex has applied their experience in manufacturing of mid-infrared fibers to develop a unique fabrication process for making fiber bundle imagers that will cover that region. This mid-infrared bundle imager will encompass 1000-10,000 fibers in 10 mm diameter.

Mid-Infrared Fiber Combiner

Fiber combiners have facilitated the creation of high power fiber lasers in the near infrared with high wall-plug efficiency. This technology is highly desired in the mid-infrared. Current mid-infrared sources are limited in their output power. High power mid-infrared can be made by the concatenation of several semiconductor lasers, such as the quantum cascade lasers. A lab prototype fiber combiner has been developed with the capacity of combining seven (7) mid-infrared lasers. The next step is to develop this concept into a commercial level product and expand the amount of lasers that can be combined.

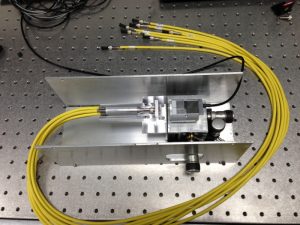

Mid-infrared Fiber-Optic Switch

IRflex has developed fiber-optic switching technology for mid-infrared applications. Our unique fiber-optic switch can be used to route a mid-infrared laser beam through transmission fiber cables to different locations. The fiber optic switch is mainly targeted for use in DIRCM (Directed Infrared Countermeasure) systems, which require switching of high power lasers. This product, however, is an excellent solution for low power applications. The switch has broad transmission (2-5 µm), fast switching time (< 2 ms), low insertion loss (< 0.2 dB) and compact. The current switch designs come in 1 by 2 and 1 by 6.

Hollow-Core Tube Lattice (HC-TL) Fiber

HC-TL fiber utilizes infrared capillaries stacked in a circular pattern producing an air core with capacity to transmit extremely high laser powers with low nonlinearities. The Fiber is optimized for beam delivery of high-energy ultra short pulse laser systems in the mid-infrared.

Active Mid-Infrared Fibers

Fiber based laser sources provide many advantages: high power, high efficiency, excellent beam quality and small footprint. Active fibers based on silica glass are limited to operation wavelength of approximately 2 µm. Alternate glass fiber compositions must be explored to develop compact high power fiber lasers beyond 2 µm. Chalcogenide based glass (glass based on S, Se and Te) are good candidates to develop active mid-infrared fibers. These fibers have wide infrared transmission and are chemically durable. IRflex has been exploring and developing several techniques to incorporate dopants into chalcogenide glasses. Concentrations as high as 2000 ppm have been achieved. These doped glasses allow for laser emission between 4-5 µm. Work is ongoing to provide commercial quality doped chalcogenide fibers.