On January 19, 2024, IRflex Corporation signed a SBIR Phase I Option contract with NAVAIR for Optical Additive Manufacturing in Mid-Wave and long-Wave Infrared Bands.

This Phase I Option award followed the successful completion of the Phase I contract signed on May 11, 2023.

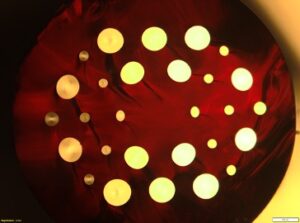

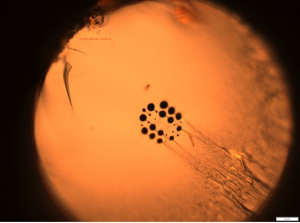

The additive manufacturing (AM) process has the potential for depositing MWIR and LWIR optical precursor materials with sufficient quality and precision for IR optical components or to perform front surface repair on existing IR optical components. The MWIR-LWIR AM will allow engineering of new compact optical systems with high imaging performance, fewer optical elements, less weight and volume, and easier alignment compared to current multi-components IR imaging optics.