On June 30th, 2021, IRflex Corporation signed SBIR 800,000US$ Phase II Contract with DOD NAVAIR for Additive Manufacturing of Inorganic Transparent Material for Advanced Optics, after successfully finishing nine-months work partnered with University of Central Florida on Phase I and Phase I Option for the same project.

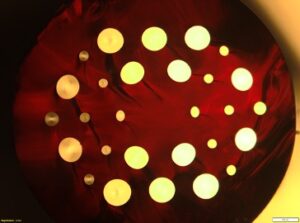

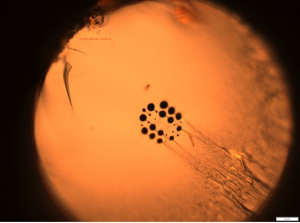

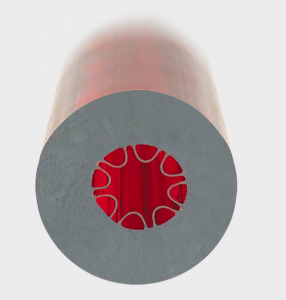

The award is principally to develop an additive manufacturing (AM) process for depositing inorganic glasses with sufficient quality and precision for free form and gradient index optics.

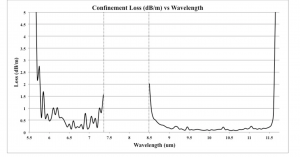

Additive manufacturing (AM) is the industrial production name for 3D printing, a computer-controlled process that creates three-dimensional objects by depositing materials, usually in layers. The benefits of AM are widely realized for structural systems; however, work on printing optical systems is still in its comparative nascency. The majority of the work has been primarily focused on polymers. There are broad arrays of weapon and surveillance systems that utilize high performance optics. The motivation is to serve the growing demand for those many applications requiring greater wavelength transmission range, hardness, and temperature stability compared to polymers. The potential for utilizing AM technology to print glass lenses will provide the ability to 1) deposit net shape or near net-shape free-form optics, 2) locally adjust the index of refraction and other optical properties such as dispersion, 3) create high precision low thermal expansion meteorological frames that can form the basis for refractive optics, and 4) repair existing optical systems.

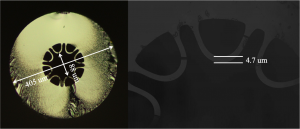

IRflex Corporation manufactures the mid-infrared fibers based on extra high purity chalcogenide glass, whose proprietary fiber technology and know-how support the Phase II project to fully develop the AM process which demonstrated in Phase I and Phase I Option, that can be applicable to an array of naval optical component geometries. Include, in the prototype demonstration, the effectiveness of fabricating fully densified optical components with precision control of the part geometry, and smooth surface quality. Fully characterize the resulting geometry, and mechanical and microstructural properties achieved through the process to validate the effectiveness of the AM process.